vina

- Polypropelene (PP)

Polypropylene (PP) is the most popular thermoplastic in use today, and still one of the fastest growing. Demand for PP continues to grow thanks to its adaptability with fillers, its ability to mimic higher-priced engineering resin properties at lower cost and the possibility to downsize and thin-wall applications. Consumption is growing at 7.6%/year worldwide, with strongest demand coming from developing markets in Asia, Africa and the Middle East. The utilisation of PP is growing in blow moulding, house wares, and in automotive bumper fascia. Metallocene catalyst technology is also expected to take it further. Moulding technologies include injection moulding, reaction injection moulding, blow moulding, rotational moulding and compression moulding.

Polypropylene is produced in both homopolymer and copolymer grades. Homopolymer polypropylene is stronger and stiffer than copolymer. Copolymer polypropylene is a bit softer, but it is tougher and more durable than homopolymer polypropylene.

APPLICATIONS

Polypropylene can be processed by virtually all thermoplastic-processing methods. Most typically PP Products are manufactured by: Extrusion Blow Moulding, Injection Moulding, and General Purpose Extrusion. Expanded Polypropylene (EPP) may be moulded in a specialist process. Auto parts, industrial fibres, food containers, and dishware

Recyled PP offers are below, "latest recycled PP" offers are at the bottom of the page:

1. High Quality PP from Malaysia

| Description | PP-1200 | PP-1250 | PP-1300 | PP-1400 | PP-1500 |

| Structure | Copo | Copo | Homo | Copo | Copo |

| Density (g/cm3) | 0.91 | 0.92 | 0.91 | 0.91 | 0.92 |

| ASTM D1238 Izod Impct (j/m) | 90-100 | 80 | 35-40 | 118-121 | 66 |

| ASTM D256 Flammability (UL 94) |

HB | HB | HB | HB | HB |

| Applications | Automotive Parts/Industrial Appliances/Furnitures/Housware | ||||

| Origin |

Malaysia |

||||

| Capacity | 200 MT Per Month, Each Grade | ||||

| Packaging | Net 25 Kg/Bag,16 MT (640 Bags in Loose Loading)/20' FCL | ||||

| Delivery |

Prompt shipment from Port Klang, Malaysia upon receipt of payment |

||||

| Remarks |

offer is subject to prior sale, MOQ 2 x 20' FCLs with one shipment, and final confirmation |

||||

2. ExxonMobil APP LNX-299

Description: ExxonMobil APP LNX-299 (Atactic

Polypropylene)

Form: Pellets

Application: Impact Modifier for PE/PP/HIPS/ABS Compounds

-Production of Waterproofing Coatings/Membranes,Modified Bitumen,

Masterbtach & HMA (Hot Melt Adhesives)

Origin :U.S.A.

Producer: ExxonMobil Chemical Company: http://www.exxonmobilchemical.com

Capacity :100 MT/Month

Packaging :Net 17 Kg/Original Export Box,19.856 MT (1,168 Boxes)/40' FCL

Delivery :Prompt shipment from US Port upon receipt of payment

Remarks :This offer is subject to prior sale, MOQ 1 x 40' FCL per

shipment and final confirmation.

Date: 20th October 2011

3. Reprocessed PP Copolymer

We regularly have Reprocessed PP Copolymer or Regranulated PP Copolymer as below:

Reprocessed PP Copolymer Blue - MFI 25/30Reprocessed PP Copolymer Green - MFI - 20/30

Reprocessed PP Copolymer Terracota - MFI - 20/30

Reprocessed PP Copolymer Red - MFI - 20/30

Reprocessed PP Copolymer White - MFI - 20/30

Reprocessed PP Copolymer Graphite - MFI - 20/30

Reprocessed PP Copolymer Black - MFI - 10/20

Reprocessed PP Copolymer Black - MFI - 20/30

Reprocessed PP Copolymer Black - MFI - 30/40

Date: 04th November 2011

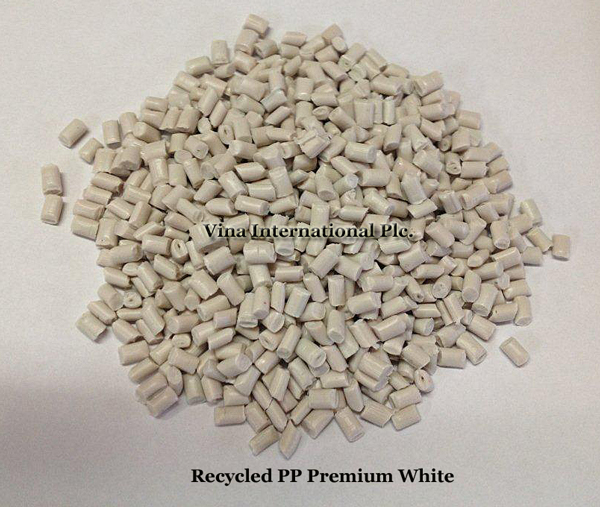

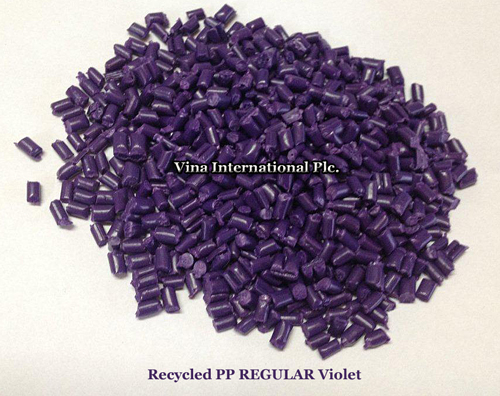

Recycled PP suitable for PP Mats, Ropes Household and Industrial applications:

We have other colours available in both Recyled PP PREMIUM as well as Recycled PP Regular grades

The above are generally available with us throughout the year(12th May, 2013)